Hot melt applicator for filters

Product Details:

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Blue

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

X

Hot melt applicator for filters Price And Quantity

- 1 Piece

Hot melt applicator for filters Product Specifications

- Industrial

- Blue

- Painted

- Automatic

- 12 Months

- 220 Volt (v)

- Electricity

Hot melt applicator for filters Trade Information

- GURUGRAM

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- 2-3 Piece Per Day

- 1 Days

- No

- Asia

- All India

Product Description

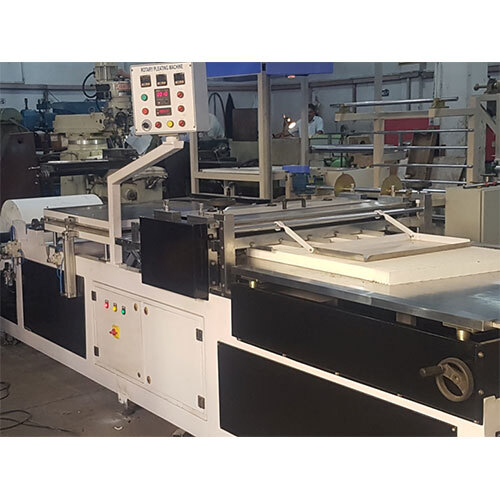

hese machines features including adjustable height of gathering tables, change in pleat depth by change of gear, digital pleat counter with marking device, digital temperature indicator controller for heating applications, mild steel fabricated structure for durable performance and presence of control panel for smooth and accurate handling of above operations.Products Details:

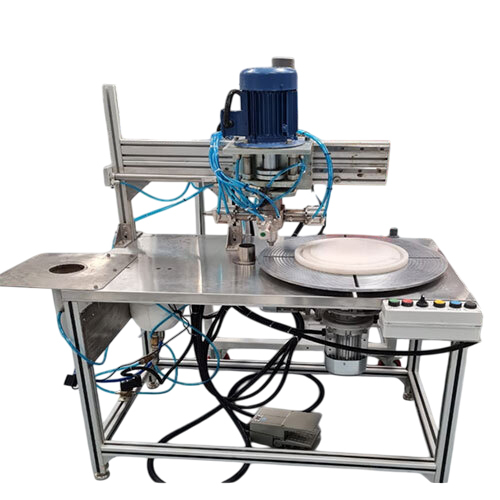

- For cylindrical conical filter

- Double dispensing heat mode

- Ring, spiral dispensing pattern

- Electrically heated tank with positive gear displacement pump for hot melt

- Tank with digital temp indicator controlling device

- Electrically heated hoses fitted with temp sensor probe digital temp indication controlling 2nos

- Pneumatically operated, electrically heated dispensing nozzle 2nos

- Facility to accommodate dispense different diameters of filters

- Pitch of the dispensing head is specified by the customers.

- Separate control panel for working motion of hotmelt dispensing unit

- Filter mounting unit to be fitted with DC drive 2nos

Advanced Automatic Solution

Experience high efficiency with this fully automatic hot melt applicator, engineered to optimize filter production lines. Its automation reduces manual intervention, ensures uniform adhesive coatings, and minimizes operational errors, making it ideal for high-volume, industrial environments.

Long-Lasting and Reliable

With a painted blue finish and robust design, this applicator withstands harsh industrial settings. It promises durability and ease of maintenance, further protected by a comprehensive 12-month warranty for buyer assurance.

Tailored for Indian Markets

Specifically crafted for industrial users throughout India, this applicator supports local voltage requirements and meets the needs of distributors, exporters, manufacturers, suppliers, and traders, making it a valuable addition to any filter production operation.

FAQ's of Hot melt applicator for filters:

Q: How does the hot melt applicator improve filter manufacturing efficiency?

A: The applicator automates adhesive application, delivering precise and consistent hot melt distribution onto filters. This reduces production time and minimizes errors, allowing manufacturers to achieve higher output and superior product quality.Q: What are the main features that make this hot melt applicator suitable for industrial use?

A: It features a blue-painted surface for durability, an automatic operating type for ease of use, reliable electric power (220 Volt), and is designed for continuous industrial application. The 12-month warranty adds an extra layer of reliability.Q: When should I service or perform maintenance on the hot melt applicator?

A: Regular maintenance is recommended as per the manufacturer's guidelines, typically after a set number of operational hours or if adhesive flow becomes inconsistent. Periodic servicing ensures optimal machine performance and longevity.Q: Where can this hot melt applicator be used within the filter manufacturing process?

A: The applicator integrates seamlessly into filter assembly lines, particularly at stages requiring the application of adhesive. It is suitable for use in various industrial plants and production facilities across India.Q: What is the process for installing the hot melt applicator in an industrial setting?

A: Installation involves connecting the applicator to a 220-volt electrical power source, calibrating the adhesive flow, and setting the machine's operation parameters for automatic use. Professional installation is recommended to ensure optimal performance.Q: How is the applicator's surface treatment beneficial for industrial environments?

A: The painted surface provides excellent resistance to wear, corrosion, and adhesive residues, extending the lifespan of the equipment and maintaining a clean operating appearance even in demanding industrial conditions.Q: What advantages do distributors and suppliers gain from offering this machine?

A: Distributors and suppliers benefit from a high-demand, reliable product with a competitive warranty, enhancing their portfolio for the Indian industrial market and providing long-term value to customers in filter manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese