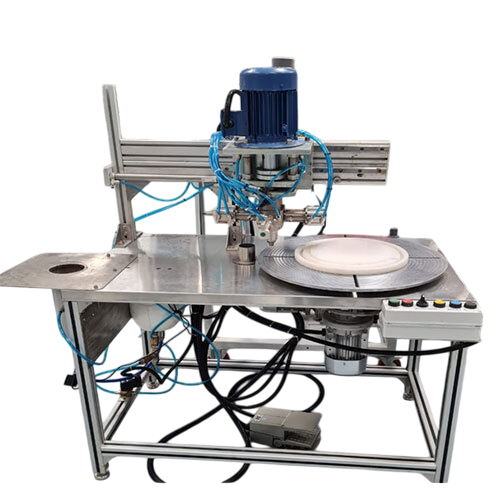

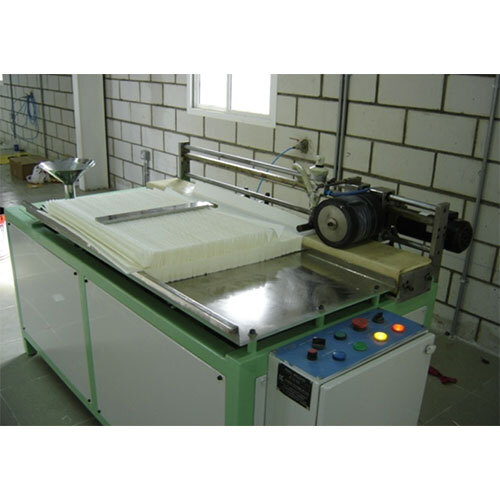

PU END CAP GASKETING MACHINE

Product Details:

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

X

PU END CAP GASKETING MACHINE Price And Quantity

- 1 Piece

PU END CAP GASKETING MACHINE Product Specifications

- Automatic

- Painted

- Industrial

- Electricity

- Semi-Automatic

- 220 Volt (v)

- 12 Months

PU END CAP GASKETING MACHINE Trade Information

- GURUGRAM

- Cheque

- 10 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Power Consumption 5.5KW Raw Material polyurethane Machine Type Automatic Voltage 415V Weight 1300 Kg Finished Gasket Width 30 mm Controller INVT Screen Size 12.1"

- Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- All India

- Power Consumption 5.5KW Raw Material polyurethane Machine Type Automatic Voltage 415V Weight 1300 Kg Finished Gasket Width 30 mm Controller INVT Screen Size 12.1"

Product Description

| Power Consumption |

|

| Raw Material |

|

| Machine Type |

|

| Voltage |

|

| Weight |

|

| Finished Gasket Width |

|

| Controller |

|

| Screen Size |

|

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese