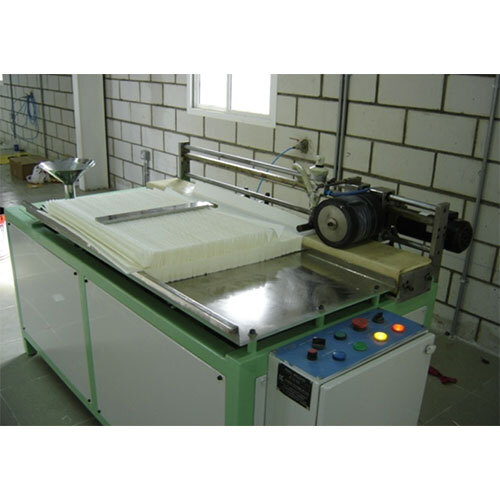

Side sealing and retainer Insertion

Product Details:

- Control System Semi-Automatic

- Machine Type Side sealing and retainer Insertion

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Color White

- Warranty 12 Months

- Click to View more

X

Side sealing and retainer Insertion Price And Quantity

- 1 Piece

Side sealing and retainer Insertion Product Specifications

- Electricity

- White

- Side sealing and retainer Insertion

- Industrial

- 12 Months

- Painted

- Semi Automatic

- Semi-Automatic

Side sealing and retainer Insertion Trade Information

- GURUGRAM

- Cash Advance (CA)

- 50 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

A quick connector coupling for a fluid line includes a female connector body defining a through bore, a tubular male member with a raised annular upset, and a retainer demountably coupled to the connector body. A seal assembly provides a fluid tight seal between the tube and body bore. A separate outer spacer is secured to the body to receive axial load of the seal assembly. The body defines spaced arcuate locking ledges having axially inward facing radial locking surfaces. The outer spacer is a continuous annular element includes an integral radial ring defining an annular axially outward facing radial abutment surface in radial abutting relation to the locking surfaces of said body ledges.Efficient Industrial Performance

This side sealing and retainer insertion machine is ideal for industrial operations requiring precise and efficient side sealing. With its semi-automatic operation, enterprises can achieve high output with reduced manual effort, making it a smart choice for scaling up productivity.

Robust Construction and Reliable Operation

Featuring a painted white finish, this machine is built for long-term operation in demanding settings. The painted surface provides corrosion resistance while the sturdy construction ensures stability during repetitive use, delivering smooth performance batch after batch.

Trusted Support and Comprehensive Warranty

Purchase with confidence, as the machine includes a 12-month warranty for manufacturing defects. Indian distributors, exporters, manufacturers, and suppliers benefit from reliable support, facilitating hassle-free integration into existing production lines.

FAQ's of Side sealing and retainer Insertion:

Q: How does the side sealing and retainer insertion machine operate?

A: The machine operates semi-automatically, requiring minimal manual intervention. Operators simply load the materials, and the machine manages side sealing and retainer insertion through its automated sequence, powered by electricity.Q: What are the typical industrial applications for this machine?

A: This equipment is designed for various industrial sectors including packaging, automotive, and manufacturing lines where precise side sealing and retainer placement are essential for product integrity.Q: When should businesses consider investing in this machine?

A: Businesses should consider this machine when production volumes increase and manual side sealing becomes time-consuming. It is especially useful for companies aiming to boost efficiency and maintain consistent output quality.Q: Where can the machine be utilized within a production facility?

A: The side sealing and retainer insertion machine can be integrated into assembly lines or dedicated workstations within industrial plants, providing flexibility to optimize workflow and space utilization.Q: What is the process for operating the machine?

A: Operation involves setting up the required materials, configuring the semi-automatic control panel, and initiating the cycle. The machine then proceeds to perform side sealing and insert retainers with minimal supervision required during the process.Q: How does the semi-automatic control system benefit users?

A: The semi-automatic control system streamlines production, minimizes operator fatigue, and ensures consistent results. This reduces errors and improves repeatability across multiple production batches.Q: What advantages does the 12-month warranty offer to buyers in India?

A: The 12-month warranty provides assurance against manufacturing defects, ensuring after-sales support and peace of mind for Indian distributors, exporters, manufacturers, suppliers, and traders.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese