FILTER END CAP PULL TEST EQUIPMENT

Product Details:

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Color White

- Warranty 1 Year

- Usage & Applications Industrial

- Click to View more

X

FILTER END CAP PULL TEST EQUIPMENT Price And Quantity

- 1 Piece

FILTER END CAP PULL TEST EQUIPMENT Product Specifications

- 1 Year

- Automatic

- White

- Industrial

- Semi-Automatic

- Electricity

- 220 Volt (v)

FILTER END CAP PULL TEST EQUIPMENT Trade Information

- GURUGRAM

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA)

- 10 Piece Per Week

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

It seems you're looking for equipment related to filter end cap pull tests, possibly from Kanwal Enterprises. These tests are often used to assess the durability and strength of filter end caps in various applications like water filtration, air filters, etc. The test typically involves applying a pulling force to the end cap of the filter to ensure that it can withstand operational stresses without failure.

Kanwal Enterprises, if they're specializing in test equipment, might offer products specifically for quality testing in filtration industries. Unfortunately, I dont have access to their current catalog, but if you're looking for specific details like technical specifications, equipment prices, or availability, I would recommend contacting them directly or checking their website.

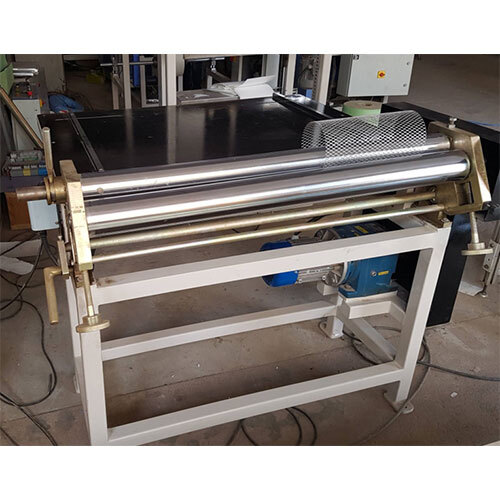

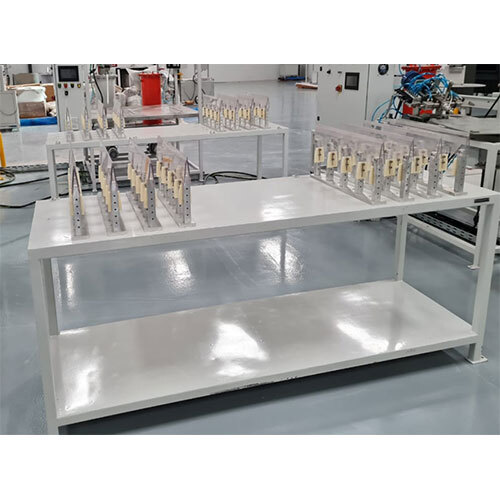

Comprehensive Testing Solution

Engineered for industrial use, this pull test equipment streamlines the quality control process for filter manufacturers and suppliers. Its semi-automatic controls ensure user-friendly operation while maintaining high precision. Dependable and robust, the equipment improves production efficiency and product reliability.

Easy Installation and Maintenance

This equipment is designed for convenient setup and minimal upkeep. With its sturdy build and straightforward controls, operators can quickly integrate it into existing workflows. Regular maintenance checks are simple and supported by a comprehensive 1-year warranty.

FAQ's of FILTER END CAP PULL TEST EQUIPMENT:

Q: How does the Filter End Cap Pull Test Equipment operate?

A: The equipment functions automatically with a semi-automatic control system, conducting pull tests on filter end caps to determine their strength and adhesion integrity. Simply connect to a 220 Volt power supply, set your parameters, and initiate the test; the machine manages the process with minimal user intervention.Q: What are the benefits of using this automatic pull test equipment?

A: Utilizing this device enhances product quality assurance, reduces manual labor, and ensures compliance with industrial standards. Its repeatable accuracy helps manufacturers, suppliers, and traders detect any potential weaknesses in filter end caps before products reach the market.Q: When should I use this equipment during the manufacturing process?

A: The pull test equipment should be used during the quality control phase after filter assembly. Performing tests at this stage helps detect bonding or adhesion issues, ensuring only structurally sound filters proceed to packaging and distribution.Q: Where is this pull test equipment commonly used?

A: This equipment is widely used in industrial facilities such as filter manufacturing plants, quality assurance laboratories, and supplier facilities across India. It is suitable for any business involved in manufacturing, supplying, or trading industrial filter products.Q: What process does the machine follow to perform the test?

A: The equipment secures the filter's end cap and applies a controlled pulling force while automatically recording the resistance and failure point. The semi-automatic system allows for quick setup and standardized, objective testing outcomes.Q: How can I benefit as a distributor or supplier by using this equipment?

A: By employing this pull test equipment, distributors and suppliers can ensure the quality and performance of their filter products, strengthening their reputation and expanding business opportunities by delivering reliable, certified goods to customers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese