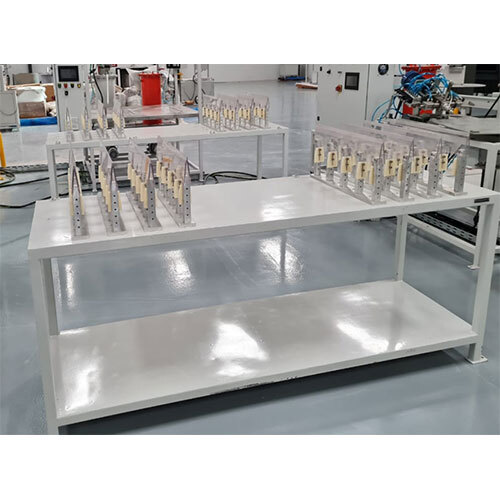

FILTER ASSEMBLY STATION

Product Details:

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Machine Type FILTER ASSEMBLY STATION

- Power Source Electricity

- Operating Type Automatic

- Color White

- Warranty 12 Months

- Click to View more

X

FILTER ASSEMBLY STATION Price And Quantity

- 1 Piece

FILTER ASSEMBLY STATION Product Specifications

- Electricity

- White

- FILTER ASSEMBLY STATION

- Semi-Automatic

- 12 Months

- 220 Volt (v)

- Industrial

- Automatic

FILTER ASSEMBLY STATION Trade Information

- GURUGRAM

- Cash in Advance (CID)

- 50 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

Air Filter Assembly refers to the process of putting together various components that form an air filtration system. It typically involves the integration of the filter media, frame, seals, gaskets, and other structural parts to create a fully functional filter that can effectively trap dust, debris, pollutants, and other contaminants from the air. Air filters are commonly used in HVAC systems, automobiles, industrial equipment, and air purifiers.

Key Components of an Air Filter Assembly:

Filter Media: The core component that captures particles from the air. It could be made from materials like fiberglass, paper, synthetic fibers, or foam. The type of media used depends on the intended application and the level of filtration required.

Frame: The frame holds the filter media in place and ensures the filter is securely mounted. Frames can be made from materials like cardboard, metal, or plastic. They come in various shapes, such as square, rectangular, or cylindrical, depending on the application.

Seals and Gaskets: These are crucial for ensuring a tight, leak-free fit between the air filter and the housing it fits into. Seals are typically made from rubber, foam, or silicone and prevent unfiltered air from bypassing the filter.

End Caps: End caps are typically used in pleated air filters and help hold the media in place. They are usually made from metal or plastic and ensure the filter maintains its shape and structural integrity.

Supporting Grills or Mesh: Some air filters are reinforced with a mesh or grill to add support and prevent the media from collapsing under airflow pressure. It also helps in protecting the filter media from physical damage.

Adhesives or Bonding Materials: These materials are used to bond the filter media to the frame, end caps, and seals, ensuring a durable and long-lasting filter assembly.

Steps in the Air Filter Assembly Process:

Preparation of Materials: Cut and prepare the filter media, frame, gaskets, and other components according to specifications.

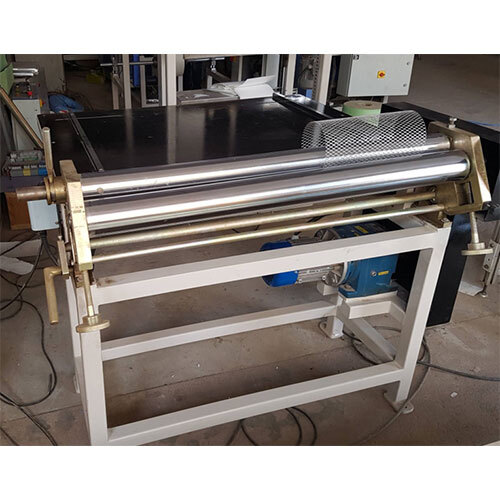

Media Placement: The filter media is either rolled, pleated, or layered and placed into the frame or between the structural parts.

Sealing: Gaskets or seals are applied to the edges of the filter to ensure an airtight seal when the filter is inserted into its housing.

Assembly: The end caps, frame, and media are securely assembled using adhesives, clips, or mechanical methods to create the final filter product.

Quality Control: After assembly, filters are tested to ensure proper functionality, including air flow resistance, filtration efficiency, and seal integrity.

Packaging and Shipment: After passing quality control, the filters are packaged for shipment and delivery.

Benefits of Efficient Air Filter Assembly:

Enhanced Air Quality: Properly assembled air filters effectively capture contaminants, improving air quality in residential, commercial, and industrial environments.

Efficiency and Durability: A well-assembled air filter ensures consistent performance over time, offering longer operational life and less frequent maintenance or replacement.

Efficient Industrial Filter Assembly

This Filter Assembly Station offers a semi-automatic control system that significantly speeds up the filter assembly process. Designed to handle heavy-duty industrial workloads, it reduces manual intervention while maintaining precise results for quality assurance. Its versatile features cater to a variety of filter types, ensuring adaptability in different manufacturing environments.

User-Friendly Operation and Maintenance

Engineered with user convenience in mind, the semi-automatic system allows operators to monitor and control operations with ease. Maintenance is straightforward, contributing to minimized downtime. The robust construction and intuitive controls facilitate a smooth workflow, ensuring consistent productivity and reliability.

FAQ's of FILTER ASSEMBLY STATION:

Q: How does the semi-automatic control system function in the Filter Assembly Station?

A: The semi-automatic control system allows operators to oversee the filter assembly process with minimal manual effort. It automates key functions while still permitting human supervision, ensuring both efficiency and quality control during industrial production.Q: What types of industries can benefit from using this Filter Assembly Station?

A: This Filter Assembly Station is ideal for any industrial setting where filter assembly is required, including automotive, chemical processing, HVAC, and water treatment sectors. Its adaptable design allows it to suit diverse manufacturing requirements.Q: When should routine maintenance be performed on this machine?

A: Routine maintenance is generally recommended at regular intervals, such as monthly or quarterly, depending on usage intensity. Regular inspections and timely servicing will help maintain optimal performance and extend the machine's lifespan.Q: Where is this Filter Assembly Station available for purchase or supply?

A: This machine is available for distribution, export, and supply throughout India. It can be purchased directly from the manufacturer, authorized suppliers, or leading industrial equipment traders.Q: What is the process for assembling filters with this machine?

A: The process involves loading filter components into the station, which then automatically maneuvers, aligns, and assembles them into finished filters. Operators supervise and initiate each cycle through easy-to-use controls, ensuring both precision and efficiency.Q: How can the Filter Assembly Station improve production efficiency?

A: By automating essential assembly functions, the station significantly reduces manual labor, speeds up production cycles, and minimizes errors. This leads to greater consistency in output and lower operational costs for manufacturers.Q: What are the main benefits of the 12-month warranty provided for this product?

A: The 12-month warranty offers peace of mind against manufacturing defects or operational issues. Customers receive prompt support and service, ensuring reliable and continuous operation throughout the warranty period.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese