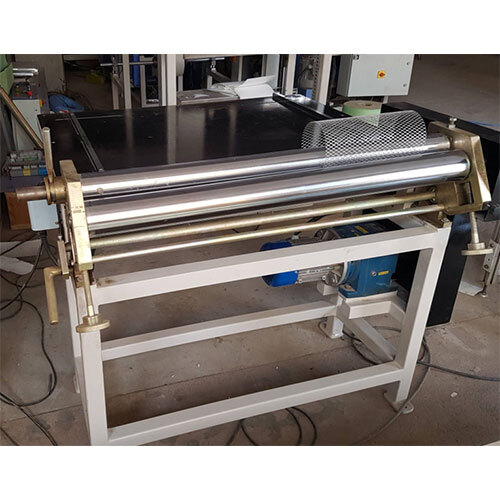

RETAINER ROLLING MACHINE

Product Details:

- Control System Semi-Automatic

- Machine Type RETAINER ROLLING MACHINE

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Click to View more

X

RETAINER ROLLING MACHINE Price And Quantity

- 1 Piece

RETAINER ROLLING MACHINE Product Specifications

- 12 Months

- RETAINER ROLLING MACHINE

- 220 Volt (v)

- Semi-Automatic

- Industrial

- Electricity

- Painted

- Automatic

RETAINER ROLLING MACHINE Trade Information

- GURUGRAM

- Cash Advance (CA)

- 100 Piece Per Month

- 1 Week

- No

- Asia

- All India

Product Description

A retainer rolling machine is typically used in manufacturing processes where components like retaining rings or washers need to be rolled or formed into specific shapes, often for mechanical or automotive applications. These machines are designed to shape materials (typically metal) into precise, consistent forms.

The general specifications and features for a retainer rolling machine might include:

1. Type of Machine:

Mechanical or Hydraulic: Hydraulic machines provide more force and are often used for heavier-duty operations, while mechanical machines might be more suitable for lighter applications.

Rotary or Linear: Some machines might use rotary forming methods, while others might move the workpiece linearly through the rolling process.

2. Capacity:

Max Diameter: The maximum size of the retainer (or ring) the machine can form. This can vary from a few millimeters up to several hundred millimeters, depending on the model.

Material Thickness: The thickness of the metal or material being formed, which might range from thin sheets to thicker materials, like in automotive or industrial parts.

3. Speed:

Roll Speed: The speed at which the machine can produce finished retainers, often measured in parts per minute (PPM).

4. Forming Method:

Rolling Mechanism: Some machines use multiple rollers or dies to form the retainer or ring shape, ensuring accuracy and uniformity.

Customization: Depending on the design of the retainer, the machine may allow adjustments to accommodate different sizes or geometries.

5. Automation:

Manual vs. Automated: Some retainer rolling machines are manual, where the operator feeds the material and sets up the machine. More advanced models are fully automated for high-volume production, reducing human intervention.

6. Control System:

Digital or CNC Controls: Some machines come with CNC (Computer Numerical Control) to allow precise adjustments and automatic operations, which are particularly useful for producing complex geometries or high-precision parts.

7. Material Compatibility:

Materials: These machines are often used with various metals such as steel, stainless steel, aluminum, or brass, depending on the industry needs.

8. Safety Features:

Machines typically come with various safety features, such as emergency stop buttons, protective guards, and interlocks to protect operators during operation.

If youre looking for a specific retainer rolling machine from Kanwal Enterprises, the exact features will depend on the model and design they offer. I would recommend reaching out directly to them for more precise product details, including the capabilities and specifications for their retainer rolling machines.

Are you looking for any particular features for your application, or need help with selecting the right machine? Let me know, and I can help further!

Efficient Rolling Technology

The Retainer Rolling Machine incorporates advanced automation for seamless industrial operations. Its automatic operating type and semi-automatic control system reduce manual labor, improving productivity and consistency. The painted surface ensures long-lasting protection against wear and environmental factors, making it a robust choice for high-volume industrial tasks.

Versatile Applications

Designed for a wide array of industrial applications, this machine supports various production lines that require reliable retainer rolling functions. Its user-friendly controls and compatibility with standard electrical systems (220V) make it suitable for many manufacturing environments throughout India.

FAQ's of RETAINER ROLLING MACHINE:

Q: How is the Retainer Rolling Machine operated?

A: The machine operates automatically with the assistance of a semi-automatic control system, requiring minimal manual intervention to manage and oversee the rolling process.Q: What are the main benefits of using this Retainer Rolling Machine?

A: Key benefits include increased productivity, precise and consistent performance, reduced manual labor, and enhanced durability due to its painted surface treatment.Q: When can the machine be serviced under warranty?

A: The machine comes with a 12-month warranty from the date of purchase, during which any manufacturing defects can be serviced by authorized technicians.Q: Where can I purchase or source this machine in India?

A: You can obtain the Retainer Rolling Machine from distributors, exporters, manufacturers, suppliers, or traders across various regions in India.Q: What is the process for installing the machine?

A: Installation typically involves connecting the equipment to a suitable 220 Volt power source, calibrating controls, and running initial operational tests as recommended in the user manual.Q: How does the machine enhance industrial workplace efficiency?

A: By automating the retainer rolling process, it allows faster throughput and reduces the need for manual adjustments, resulting in streamlined production and less downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese