END CAP PU DISPENSER

Product Details:

- Machine Type END CAP PU DISPENSER

- Power Source Electricity

- Operating Type Automatic

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

X

END CAP PU DISPENSER Price And Quantity

- 1 Piece

END CAP PU DISPENSER Product Specifications

- END CAP PU DISPENSER

- Industrial

- Electricity

- Automatic

- 12 Months

END CAP PU DISPENSER Trade Information

- GURUGRAM

- Cash Advance (CA)

- 10 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

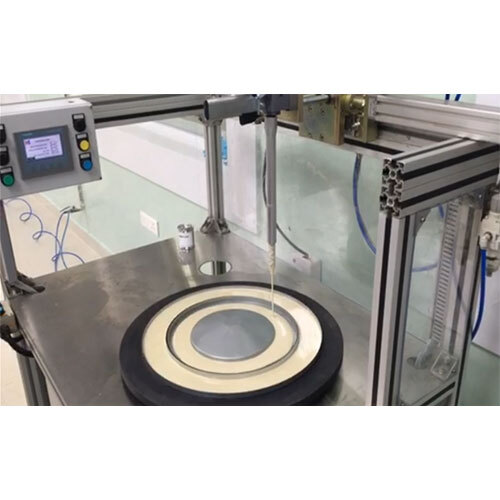

Adhesive Dispenser for End Caps assist filter manufacturers in improving productivity in bonding, sealing as well as gasketing filter media. These adhesive dispensers for end caps come with stainless steel fabricated tanks with maximum tank capacity of 60 ltrs and tank mountings comprising air inlet with slide valve, safety valve, FRL unit, pressure gauge, air release valve and adhesive inlet. Some other options these dispensers come with include bottom drain valve and adhesive outlet, rotating table for suiting different cap diameters, DC drive for table rotating as well as provision of adjusting the nozzle for various diameters.Specifications

- Maximum tank capacity 60 ltrs

- SS fabricated tank.

- Tank mountings safety valve, air inlet with slide valve, FRL unit, air release valve, Pressure gauge & adhesive inlet.

- Bottom drain valve and adhesive outlet.

- Rotating table to suit different cap diameters.

- DC drive for table rotating

- Nozzle will be adjusted for various diameter

Efficient Industrial Solution

The END CAP PU DISPENSER offers an automated solution for accurate and consistent application of polyurethane in end cap sealing processes. Designed specifically for industrial use, it drastically improves operational speed and minimizes errors typically associated with manual methods. This machine is suitable for diverse industries aiming to optimize production without compromising on quality.

User-Friendly & Reliable

Equipped with an easy-to-operate interface, the END CAP PU DISPENSER ensures hassle-free integration into existing workflows. Its robust electric-powered operation, coupled with a 12-month warranty, assures long-lasting reliability and peace of mind for users. Assembled and supplied in India, it meets high standards of efficiency required by modern factories.

FAQ's of END CAP PU DISPENSER:

Q: How does the END CAP PU DISPENSER enhance industrial PU application processes?

A: The automatic dispenser streamlines the application of polyurethane on end caps, delivering uniform and precise results while reducing manual labor and minimizing human error.Q: What industries or applications are best suited for using the END CAP PU DISPENSER?

A: This machine is ideal for industries engaged in the production of filters, automotive components, and products that require reliable PU end cap sealing in bulk manufacturing environments.Q: When should maintenance be performed on the END CAP PU DISPENSER?

A: Routine maintenance is recommended as per the manufacturer's guidelines-generally following every production cycle or as indicated in the user manual-to ensure optimal performance and maximize the lifespan of the machine.Q: Where is the END CAP PU DISPENSER manufactured and distributed?

A: The machine is manufactured in India and is available locally and internationally through a network of distributors, exporters, suppliers, and traders.Q: What is the process for using the END CAP PU DISPENSER?

A: To operate, connect the dispenser to an electric power source, select your settings on the control interface, and initiate the automatic dispensing process for consistent PU application with minimal manual intervention.Q: What benefits does this PU dispenser offer over manual methods?

A: Key benefits include higher productivity, improved application accuracy, reduced wastage, lower labor requirements, and consistent results across large production batches.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese