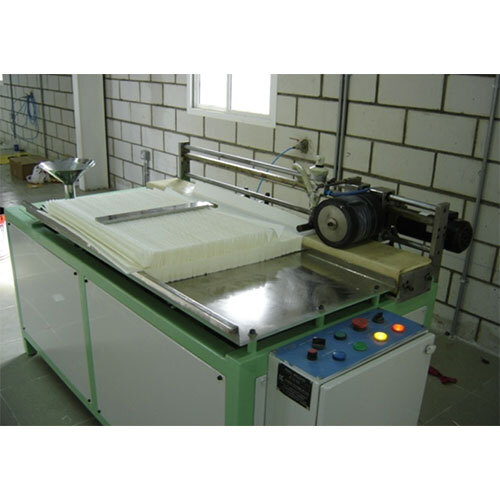

HIGH SPEED ROTARY PLEATER

Product Details:

- Control System Semi-Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

HIGH SPEED ROTARY PLEATER Price And Quantity

- 1 Piece

HIGH SPEED ROTARY PLEATER Product Specifications

- Industrial

- Painted

- Electricity

- 220 Volt (v)

- 12 Months

- Automatic

- Semi-Automatic

HIGH SPEED ROTARY PLEATER Trade Information

- gurugram

- Cash Advance (CA)

- 20 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

Are you looking forRotary Pleating Machine?Kanwal Enterprisesis well-recognizedRotary Pleating Machine Manufacturers In Haryanathat offer you the best quality products to meet your industry need. We blend our innovation and creativity to bring exceptional solutions. OurRotary Pleating Machineis highly durable and robust construction that helps them to stand out of the curve. We work on our toes to deliver the best designRotary Pleating Machinethat is highly functional and needs less maintenance. Our Rotary Pleating Machine is beneficial to boost the productivity of your industry.

State-Of-Art-Infrastructure

Our complete range is manufactured in our in-house manufacturing facility and is equipped with modern machinery and the latest technology. We are capable enough to design the Rotary Pleating Machine with top-quality material and with the utmost precision. We work beyond boundaries to deliver you nothing but the best. We have a well-trained and experienced team of professionals who never mind putting extra effort into checking the quality standard of our Rotary Pleating Machine before delivering it to the end user. We strictly follow the industry norms.

Features Of Our Rotary Pleating Machine

- High-functionality

- Excellent and smooth finishing

- Corrosion and rust resistant

- Long functional life

- Customized as per the client's demand

- Eminent performance

- Rigid and robust structure

Get The Quality Assured Rotary Pleating Machine Now!

We are counted among Top10 Rotary Pleating Machine Exporters And Suppliers In India, are here to deliver you quality Rotary Pleating Machine at an affordable range. We are dedicated to catering to specific customer designs. So without any delay, get in touch with our experts to clear all your doubts. So, if you want to place your order, send enquiries on the website or directly call us.

Rotary Pleating Machines are of embossing type and are designed for achieving high speed production. These machines are designed to precision handle the demands of producing pleats in a wide range of widths as well as depth options. As best suited machines, these Rotary Pleating machines are specially suited for places where there is requirement of bulk production of single specific pleat depth and filter size. Here, the pleats of different sizes can be developed through changing set of pleating rollers. Further, the use of different size rollers are also used for coming up with pleats of different pleat sizes. The equipment comes with automatic pre-slitting, electric heating system, pleating system as well as a counter system so as to ensure in them optimum functionality support.

Products details:

- Maximum width of roller 350 - 1000 mm.

- Pleat depth variable 12-48 mm.

- Filter paper roll mounting stand.

- Facility to adjust the height of gathering table as per pleat depth.

- Change of pleat depth by just replacing one gear.

- Counter for counting no. of packs.

- Facility to change the marking rollers.

- High speed pleating m/c with DC variable speed drive.

Precision Engineering for Industrial Efficiency

The High Speed Rotary Pleater is meticulously designed to deliver high performance in industrial settings. Utilizing a semi-automatic control system, it guarantees uniform pleating at remarkable speeds, making it a preferred choice for manufacturers seeking consistent product quality and productivity.

Reliable and Durable Construction

Built with industrial-grade materials and finished with a painted surface treatment, the High Speed Rotary Pleater ensures longevity even in rigorous working environments. Its robust construction minimizes maintenance needs, offering businesses peace of mind throughout its warranty period.

FAQ's of HIGH SPEED ROTARY PLEATER:

Q: How does the High Speed Rotary Pleater operate in an industrial environment?

A: The machine utilizes a semi-automatic control system, allowing operators to manage settings easily while it automatically performs high-speed pleating, ensuring accuracy and efficiency in industrial production processes.Q: What are the typical applications for this rotary pleater?

A: Commonly, the High Speed Rotary Pleater is used in industries such as filtration, air purification, and other manufacturing sectors where precise pleating of materials is essential for quality filtration products.Q: When is the best time to perform maintenance on this pleater to ensure optimal performance?

A: Routine maintenance should be conducted as per the manufacturer's schedule, typically every few months or after significant production cycles, to keep the machine running efficiently and extend its service life.Q: Where can this equipment be sourced, and who can purchase it?

A: This product is available across India through various channels, including distributors, exporters, manufacturers, suppliers, and traders, catering to businesses looking for reliable industrial machinery.Q: What is the process for installing and integrating the High Speed Rotary Pleater?

A: Installation involves connecting the machine to a 220 Volt electricity supply, setting up the control system, and calibrating it for specific materials. Detailed guidance is provided in the user manual, and technical support is available if needed.Q: How does the 12-month warranty benefit buyers?

A: The 12-month warranty ensures customer confidence, covering repairs or replacements due to manufacturing defects, and provides support for operational issues during the initial year of usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese