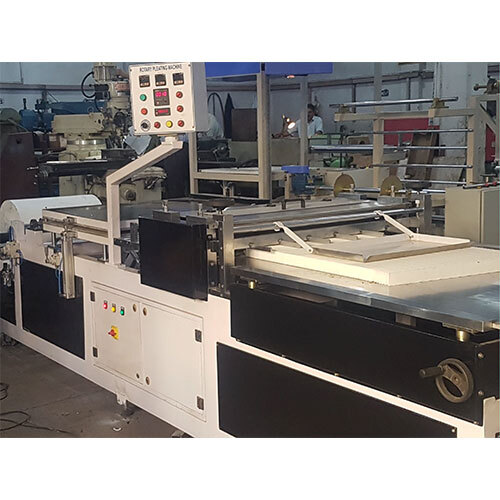

VULCANIZING PRESS MACHINE

Product Details:

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Blue

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

VULCANIZING PRESS MACHINE Price And Quantity

- 1 Piece

VULCANIZING PRESS MACHINE Product Specifications

- Industrial

- Blue

- 12 Months

- Automatic

- Semi-Automatic

- Electricity

- Painted

Product Description

A Vulcanizing Press Machine is a key piece of equipment used in the process of vulcanization, which is a chemical process that involves heating rubber (or similar materials) with sulfur to improve its strength, elasticity, and durability. This process is essential in the manufacturing of tires, rubber belts, hoses, gaskets, and other rubber products.

Key Components & Functions:

-

Heating Plates: The machine consists of two or more large metal plates that are heated to a specific temperature. These plates are where the rubber products are placed for vulcanization. The plates press against the rubber to apply both heat and pressure.

-

Pressure Mechanism: The press machine applies pressure to the rubber, which helps to shape the material and enables the sulfur to crosslink the rubber molecules. This ensures the rubber becomes more resilient and less prone to wear, aging, and environmental damage.

-

Control System: Vulcanizing press machines are equipped with advanced controls to regulate both the temperature and pressure applied during the vulcanization process. This is crucial because both the temperature and time must be precisely controlled to achieve the desired properties of the final rubber product.

-

Mold: In many applications, the press machine includes molds to shape the rubber into a specific form or product. For example, when producing rubber tires, molds are used to shape the rubber into tire treads.

Types of Vulcanizing Press Machines:

-

Hydraulic Vulcanizing Press: Uses hydraulic pressure to press the rubber between heated plates. This is one of the most common types and is often used for large-scale production of rubber products.

-

Mechanical Vulcanizing Press: Uses mechanical force, often driven by a motor, to apply pressure to the rubber. These are typically used for smaller items or lower-volume production.

-

Vacuum Vulcanizing Press: Used when a vacuum is required during vulcanization to prevent air bubbles or to achieve a specific density in the rubber product.

-

Rotary Vulcanizing Press: The rubber product or mold rotates as the heat and pressure are applied, ensuring an even vulcanization process for products that require uniformity, such as rubber hoses.

Efficient Industrial Vulcanization

Our Vulcanizing Press Machine streamlines industrial vulcanization, offering fast, reliable results for a variety of materials. Its automatic operation reduces manual effort, while the semi-automatic control system ensures both safety and precision in every batch.

Durable Construction and Optimal Performance

Built to withstand rigorous industrial usage, the machine's painted blue surface protects against wear and environmental factors. The robust design, paired with an electric power source, delivers consistent, high-quality output suitable for continuous operations.

FAQ's of VULCANIZING PRESS MACHINE:

Q: How is the Vulcanizing Press Machine operated and controlled?

A: The machine is designed for automatic operation, simplifying the vulcanization process. It uses a semi-automatic control system, allowing operators to manage key functions while the system oversees consistent and efficient performance.Q: What are the primary industrial applications of this machine?

A: This press machine is commonly used in industrial settings, especially for vulcanizing rubber goods and conveyor belts. Its design supports heavy-duty tasks, making it essential for factories, manufacturing units, and material processing facilities.Q: When should I schedule maintenance for optimal machine performance?

A: Routine maintenance is recommended at regular intervals, ideally every few months or after extended periods of intensive use. Adhering to the service schedule outlined in the manual helps ensure maximum lifespan and consistent functionality.Q: Where is this Vulcanizing Press Machine manufactured and supplied from?

A: The machine is manufactured, supplied, and exported directly from India. We serve as a manufacturer, distributor, exporter, supplier, and trader, delivering products both domestically and internationally.Q: What is the surface treatment and why is it beneficial?

A: The machine's surface is treated with durable blue paint, enhancing longevity and providing resistance against abrasion, corrosion, and industrial wear. This ensures reliable operation even in harsh environments.Q: How does the warranty benefit buyers?

A: A 12-month warranty is provided, covering manufacturing defects and core mechanical faults. This gives buyers confidence in their investment, ensuring prompt support and parts replacement if needed during the warranty period.Q: What is the process involved in using the Vulcanizing Press Machine?

A: The process begins by preparing the materials for vulcanization. After placing them in the machine, operators follow the semi-automatic controls to set parameters. The machine then applies controlled heat and pressure, efficiently completing the vulcanization cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese