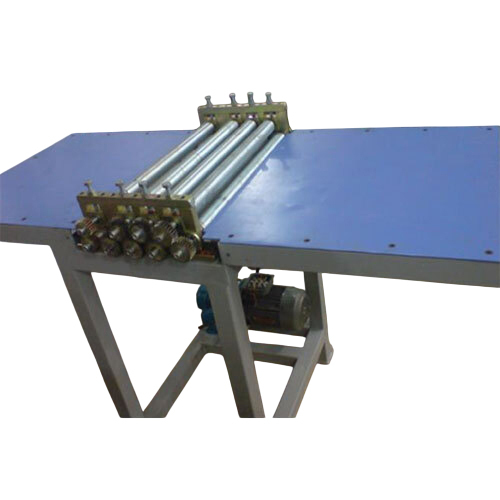

VIBRATION TEST EQUIPMENT

Product Details:

- Control System Fully Automatic

- Voltage 220 Volt (v)

- Machine Type VIBRATION TEST EQUIPMENT

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Blue

- Click to View more

VIBRATION TEST EQUIPMENT Price And Quantity

- 1 Piece

VIBRATION TEST EQUIPMENT Product Specifications

- Automatic

- VIBRATION TEST EQUIPMENT

- 220 Volt (v)

- Blue

- Industrial

- Fully Automatic

- Painted

- Electricity

- 12 Months

VIBRATION TEST EQUIPMENT Trade Information

- 10 Piece Per Week

- 7 Days

- All India

Product Description

Vibration Test Equipment refers to instruments and systems used to simulate and measure the effects of vibration on materials, products, or components. These tests are essential in industries like automotive, aerospace, electronics, and manufacturing to evaluate how products perform under conditions that mimic real-world vibrations, which could be due to transportation, machinery, or natural forces.

Key Functions of Vibration Test Equipment:

-

Simulating Real-World Vibrations:

- Vibration test equipment is designed to recreate specific vibration environments that a product or component might experience during its lifecycle. This includes testing for vibrations caused by transportation, engine operation, wind forces, and seismic activity.

-

Measuring Structural Response:

- The equipment measures how a product or material responds to vibration, including any potential damage, fatigue, or failure points. This helps in understanding the durability and reliability of the item.

-

Quality Control:

- By subjecting components to controlled vibration tests, manufacturers can ensure that products meet required standards for performance and safety. This is especially important for high-stakes industries like aerospace or automotive, where failure can be catastrophic.

-

Design and Development:

- Vibration testing is used early in the design and development stages to identify potential issues with a product's construction or material choice, reducing the risk of costly failures later.

Types of Vibration Test Equipment:

-

Shakers (Vibration Test Machines):

-

The most common type of vibration test equipment, a shaker is a mechanical device that generates vibrations. Shakers can operate on various frequencies and amplitudes to simulate different vibration environments.

-

Types of Shakers:

- Electrodynamic Shakers: Use electromagnetic force to generate vibrations and are suitable for testing both small and large samples. These are widely used in research and industry due to their versatility.

- Hydraulic Shakers: Use hydraulic power to generate vibrations. These are generally used for larger specimens or when high forces are needed.

- Servo-hydraulic Shakers: Controlled using hydraulic actuators, these are used for highly dynamic testing where precise control of frequency and amplitude is required.

-

-

Vibration Controllers:

- Vibration controllers are electronic systems that control the shaker's motion. They adjust the frequency, amplitude, and waveform of the vibrations to replicate specific test conditions.

- They often have software that allows users to program complex vibration profiles and sequences.

-

Accelerometers:

- These sensors measure the acceleration of a vibrating object. They are attached to the product or specimen to monitor how the vibration affects the material.

- The data from accelerometers can help in analyzing the intensity, frequency, and response of the vibrations.

-

Data Acquisition Systems:

- These systems collect and record data from vibration tests. They capture signals from accelerometers and other sensors to analyze the performance and response of the product during testing.

-

Fixture and Mounting Systems:

- Fixtures are used to hold the test sample in place during vibration testing. Proper mounting is critical to ensure that the test results are accurate and that the vibrations are transmitted to the specimen properly.

-

Vibration Simulators:

- Some vibration test equipment includes simulators, which can mimic real-world conditions based on data from actual environments. For example, a road simulation machine can replicate the vibrations experienced by a car driving over rough terrain.

Vibration Test Methods:

-

Sine Vibration Testing:

- In sine testing, the shaker generates a continuous sinusoidal vibration at a specific frequency. It is typically used to evaluate the resonance frequencies of a product to ensure that it does not fail under certain conditions.

-

Random Vibration Testing:

- Random vibration testing is used to simulate unpredictable vibrations, such as those that occur during transportation or exposure to environmental forces. The shaker produces vibrations at random frequencies, and the test evaluates how well the product withstands these variable conditions.

-

Shock Testing:

- Shock testing simulates abrupt, high-intensity forces like those experienced during impact or crash situations. The shaker applies sudden, intense vibrations to the product, helping to identify potential failures due to quick acceleration or deceleration.

-

Swept Sine Testing:

- This test involves gradually sweeping through a range of frequencies while monitoring the response of the product. It's typically used to identify resonance frequencies and ensure the product can handle vibrations across the entire spectrum.

-

Half-Sine Pulse Testing:

- A half-sine pulse test simulates the impact of a sudden shock. The shaker produces a pulse-like vibration with a half-sine wave form, commonly used for simulating mechanical impacts.

Applications of Vibration Test Equipment:

-

Automotive Testing:

- Testing vehicle components like suspension systems, engine parts, and electronics for durability under road vibrations.

-

Aerospace Testing:

- Simulating the extreme vibrations experienced by aircraft or spacecraft during flight, takeoff, and landing, including conditions like turbulence or engine vibrations.

-

Electronics Testing:

- Ensuring that electronic devices like smartphones, computers, or circuit boards can withstand vibrations during transport or everyday use.

-

Industrial Machinery Testing:

- Checking the resilience of machinery components, such as turbines, motors, and gears, to ensure they dont fail under operational vibrations.

-

Packaging and Shipping:

- Packaging companies use vibration tests to simulate the conditions products will experience during shipping, ensuring that packaging materials are adequate to protect goods.

-

Structural Testing:

- Testing buildings, bridges, and other structures to ensure they can withstand vibrations from sources like earthquakes, traffic, or machinery.

Advantages of Vibration Testing:

-

Improved Product Reliability:

- Vibration testing helps manufacturers identify weaknesses in products before they reach the market, reducing the likelihood of failures in the field.

-

Regulatory Compliance:

- Many industries are subject to strict vibration-related regulations. Using vibration testing equipment helps ensure products meet the necessary standards and pass certifications.

-

Cost Savings:

- Identifying potential issues early in the development process through vibration testing can save costs by reducing product recalls and post-release failures.

-

Enhanced Safety:

- Vibration testing ensures that components can handle the stresses they may encounter during use, improving the safety of end-users.

Key Manufacturers of Vibration Test Equipment:

- Bruel & Kjaer

- Thermotron

- Labworks Inc.

- Shaker Systems

- Weiss Technik

Efficient and Reliable Testing Solution

Experience seamless industrial testing with our fully automatic Vibration Test Equipment. Equipped with a modern control system and powered by standard 220 Volts, this equipment ensures accurate and repeatable results for your vibration analysis needs. Its blue, painted finish not only provides durability but also adds a professional look to your lab or factory.

Comprehensive Service across India

As a trusted distributor, exporter, and supplier, we deliver our Vibration Test Equipment to industries all over India. Our expertise as a manufacturer and trader guarantees you receive robust customer support, timely delivery, and reliable after-sales service, matching our commitment to excellence.

FAQ's of VIBRATION TEST EQUIPMENT:

Q: How does the fully automatic control system enhance the performance of vibration test equipment?

A: The fully automatic control system simplifies operation and improves testing precision. By automating key functions, the system minimizes manual intervention, reduces the chance of human error, and streamlines the testing process for consistent and repeatable outcomes.Q: What industries typically use this vibration test equipment in India?

A: This equipment is widely utilized in industries such as automotive, aerospace, electronics, manufacturing, and quality assurance labs. Its robust design and automated operation make it ideal for any sector that requires reliable vibration analysis and durability testing.Q: When is vibration test equipment essential during industrial processes?

A: Vibration testing is crucial during product development, quality assurance, and maintenance stages. It helps identify potential structural weaknesses or performance issues, ensuring that components can withstand real-world operational stresses before deployment.Q: Where can this equipment be installed, and is special infrastructure needed?

A: The equipment can be installed in laboratories, factory testing areas, and quality control departments. It requires access to a stable 220 Volt electricity supply but does not demand intricate infrastructure beyond standard safety measures and a flat surface for installation.Q: What is the typical operating process for this vibration test equipment?

A: Operation involves placing the test specimen on the equipment platform, configuring the test parameters via the automatic control system, and initiating the vibration test. The machine will automatically execute the programmed sequence, record data, and alert the user upon completion.Q: What are the main benefits of using your vibration test equipment for industrial applications?

A: Primary benefits include enhanced testing accuracy, consistent repeatability, time efficiency, reduced manual labor, and reliable identification of product weaknesses. The durable, painted exterior ensures longevity, while the 12-month warranty offers peace of mind.Q: How can customers in India obtain support or service for their vibration test equipment?

A: As a manufacturer, distributor, exporter, and service provider, we offer comprehensive technical support, maintenance, and warranty services across India. Customers can contact our dedicated service team for prompt assistance or to schedule onsite visits.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese