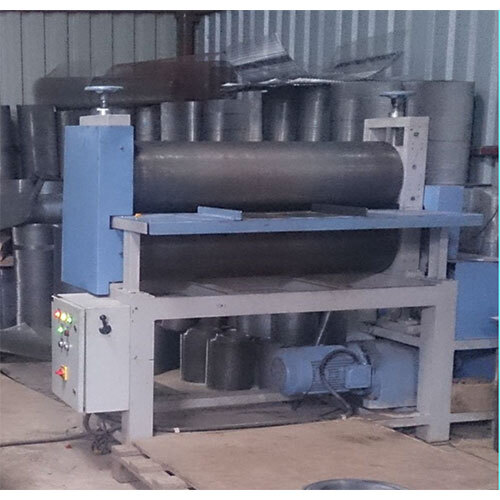

PNEUMATIC PRESS

Product Details:

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Silver

- Warranty 12 Months

- Click to View more

X

PNEUMATIC PRESS Price And Quantity

- 1 Piece

PNEUMATIC PRESS Product Specifications

- 220 Volt (v)

- Electricity

- Industrial

- Painted

- Semi-Automatic

- Silver

- Automatic

- 12 Months

PNEUMATIC PRESS Trade Information

- GURUGRAM

- 2-3 Piece Per Day

- 1 Days

- Contact us for information regarding our sample policy

Product Description

Advanced Automation for Industrial Efficiency

This pneumatic press integrates automatic operation with a semi-automatic control system, enabling precise and repeatable pressing tasks. Its design supports diverse industrial applications, from assembly lines to metal forming, ensuring consistent, high-quality results with every use.

Sturdy Design and Reliable Performance

Crafted with a silver finish and robust painted surface, the press resists corrosion and endures heavy-duty use. The 12-month warranty reflects its reliability and our commitment as leading distributors, manufacturers, and exporters in India.

FAQ's of PNEUMATIC PRESS:

Q: How does the pneumatic press operate in an industrial environment?

A: The pneumatic press works automatically, utilizing electricity and compressed air, making it suitable for tasks such as forming, assembling, and punching. Its semi-automatic control system allows operators to manage processes efficiently, increasing productivity.Q: What are the key benefits of choosing this pneumatic press?

A: This press offers rapid, repeatable results with minimal operator intervention. Its sturdy construction, semi-automatic controls, and 12-month warranty combine to deliver reliability, ease of operation, and reduced downtime in industrial settings.Q: When should regular maintenance be performed on the pneumatic press?

A: Routine maintenance, such as checking connections, inspecting painted surfaces, and verifying pneumatic operations, should occur every few months or as specified in the user manual, ensuring long-term performance and warranty coverage.Q: Where can this pneumatic press be installed?

A: Designed for industrial use, the press should be installed in well-ventilated, dry factory environments with access to a 220 Volt electrical supply and suitable pneumatic lines for trouble-free operations.Q: What is the typical process of operating the pneumatic press?

A: Operators load the material, select desired settings using the semi-automatic controls, and activate the automated press cycle. The machine completes the pressing task efficiently, and safety protocols should be followed throughout the process.Q: In which industries is this pneumatic press most commonly used?

A: It is widely utilized in manufacturing, metalworking, automotive, and electronics industries, where precise, repeated pressing actions are essential for assembly, forming, or stamping operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese