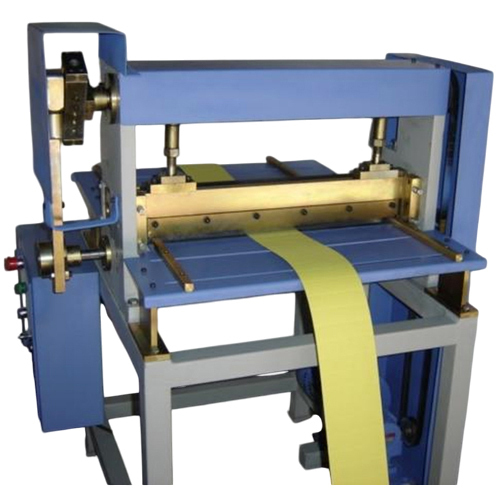

Pleating with unwinder & online slitter

Product Details:

- Voltage 220 Volt (v)

- Control System Fully Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Red

- Warranty 12 Months

- Click to View more

X

Pleating with unwinder & online slitter Price And Quantity

- 1 Piece

Pleating with unwinder & online slitter Product Specifications

- 220 Volt (v)

- Red

- Automatic

- Industrial

- Electricity

- Fully Automatic

- Painted

- 12 Months

Pleating with unwinder & online slitter Trade Information

- 2-3 Piece Per Day

- 1 Days

Product Description

Take advantage of this in-demand Pleating with Unwinder & Online Slitter, a gilt-edged solution tailored for rigorous industrial demands. Boasting lavish engineering and a noble design, our fully automatic system features a robust control setup, vibrant red finish, and efficient painted surface treatment for longevity. Operating at 220 volts and powered by electricity, this machinery streamlines processes with unparalleled accuracy. Supported by a 12-month warranty, it is distributed, exported, manufactured, supplied, and traded across India, offering dependable performance as well as advance purchase opportunities for astute businesses.

Advanced Features & Versatile Suitability

The Pleating with Unwinder & Online Slitter stands out with its special gilt-edged features: a fully automatic control system, optimal voltage operation, and a durable red painted exterior. Its uncompromising automated performance delivers precision pleating and online slitting, ideal for a variety of industrial applications. This noble machine streamlines manufacturing processes with efficiency and reliability, making it suitable for large-scale industries seeking to elevate their operations with minimal operator oversight and maximum output.

Export Markets, Packaging & Logistics

We offer our Pleating with Unwinder & Online Slitter to primary export markets, supported by secure, durable packaging for safe arrival. The proposal amount includes comprehensive transport services from the designated FOB port, ensuring smooth logistics and secure delivery. From order completion to final shipment, clients experience prompt professional service. Our machinery reaches clients worldwide, ensuring their industrial processes benefit from swift installation and operation, meeting international standards and timeframes.

Advanced Features & Versatile Suitability

The Pleating with Unwinder & Online Slitter stands out with its special gilt-edged features: a fully automatic control system, optimal voltage operation, and a durable red painted exterior. Its uncompromising automated performance delivers precision pleating and online slitting, ideal for a variety of industrial applications. This noble machine streamlines manufacturing processes with efficiency and reliability, making it suitable for large-scale industries seeking to elevate their operations with minimal operator oversight and maximum output.

Export Markets, Packaging & Logistics

We offer our Pleating with Unwinder & Online Slitter to primary export markets, supported by secure, durable packaging for safe arrival. The proposal amount includes comprehensive transport services from the designated FOB port, ensuring smooth logistics and secure delivery. From order completion to final shipment, clients experience prompt professional service. Our machinery reaches clients worldwide, ensuring their industrial processes benefit from swift installation and operation, meeting international standards and timeframes.

FAQ's of Pleating with unwinder & online slitter:

Q: How does the Pleating with Unwinder & Online Slitter operate automatically?

A: The machine features a fully automatic control system that manages both the unwinding and slitting processes, ensuring consistent and precise pleating without manual intervention.Q: What industries benefit most from this machinery?

A: This equipment is tailored for industrial applications where high-volume, accurate pleating and slitting are required, such as textile manufacturing, filtration, and material processing sectors.Q: When should I schedule advance purchase for bulk orders?

A: It is advisable to place advance purchase orders as early as possible due to the in-demand status of this product, ensuring timely manufacturing, shipment, and installation at your facility.Q: Where is this machinery manufactured and supplied from?

A: Our Pleating with Unwinder & Online Slitter is manufactured, supplied, distributed, and exported from India, serving both domestic and international industrial clients.Q: What is the benefit of choosing a fully automatic pleating and slitting system?

A: Choosing this fully automatic system minimizes manual handling, increases precision and speed, reduces operational errors, and enhances overall productivity in your industrial process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese