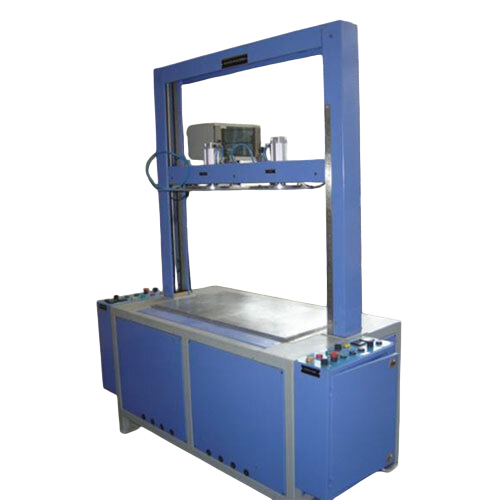

Mini Perforation machine

Product Details:

- Control System Semi-Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

X

Mini Perforation machine Price And Quantity

- 1 Piece

Mini Perforation machine Product Specifications

- 220 Volt (v)

- Semi-Automatic

- Painted

- Electricity

- Semi Automatic

- Industrial

- 12 Months

Mini Perforation machine Trade Information

- GURUGRAM

- Cash Advance (CA)

- 10 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

A Mini Perforation Machine is a compact, specialized machine designed for creating small, precise perforations (holes or slits) in various materials such as paper, plastic, metal, or fabric. These machines are commonly used in industries that require perforated products for applications like packaging, printing, or decorative designs.

How a Mini Perforation Machine Works:

-

Perforation Process:

- The machine uses a sharp, rotating punching tool or die to create a series of holes or slits in the material.

- The material passes through a set of rollers, and the perforation tool creates holes in a regular pattern.

- These holes could be circular, square, or any other shape depending on the specific die used.

-

Adjustable Settings:

- Hole Size: Many mini perforation machines allow for the adjustment of the size of the holes.

- Hole Spacing: The distance between the perforations can be adjusted for different applications.

- Speed: Some models feature adjustable speed settings, enabling faster or slower perforation based on the material being processed.

Versatile Industrial Applications

The Mini Perforation Machine is widely employed in industries requiring precise perforation, including paper processing, packaging, textiles, and labeling. Its versatility allows it to handle different materials with consistent accuracy, making it ideal for both large-scale manufacturing and specialized production needs.

Efficient Semi-Automatic Operation

Designed for ease of use, the semi-automatic control system minimizes manual intervention while maintaining high productivity. Operators can perform setup and oversee functions effortlessly, which increases efficiency and reduces the likelihood of errors during production.

FAQ's of Mini Perforation machine:

Q: How does the Mini Perforation Machine operate?

A: The Mini Perforation Machine uses a semi-automatic control system, allowing users to efficiently manage perforation tasks with minimal manual input. It connects to a 220-volt electric power source and features intuitive controls for easy operation.Q: What materials can this machine perforate?

A: This perforation machine is suitable for a variety of industrial materials, including paper, cardboard, thin plastics, textiles, and packaging films, making it adaptable to multiple industries.Q: Where is the Mini Perforation Machine commonly used?

A: The machine finds its primary usage in industrial settings such as manufacturing units, printing houses, packaging facilities, and textile plants across India, where precise and speedy perforation is required.Q: What is the process for perforating materials with this machine?

A: To perforate materials, load the desired substrate into the machine, adjust the settings as required, and activate the semi-automatic control. The machine then completes the perforation process, delivering uniform results efficiently.Q: What are the benefits of using this semi-automatic perforation machine?

A: Users benefit from increased productivity, consistent perforation quality, easy maintenance due to its durable painted surface, and reduced operational hassle thanks to the semi-automatic system. The included 12-month warranty provides added confidence.Q: When should maintenance be performed on the Mini Perforation Machine?

A: Regular maintenance should be carried out according to the manufacturer's guidelines, typically after set operational cycles or as indicated by performance metrics, to ensure durability and optimal function.Q: How can customers in India access service or support for this machine?

A: As the machine is distributed, manufactured, and supplied by reputable companies in India, customers can contact their respective supplier or dealer for service, technical support, or warranty claims during the 12-month warranty period.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese