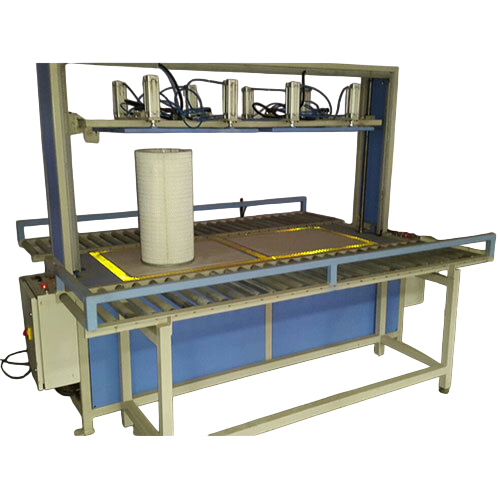

HOT PLATE FOR END CAP CURING

Product Details:

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Color Blue

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

HOT PLATE FOR END CAP CURING Price And Quantity

- 1 Piece

HOT PLATE FOR END CAP CURING Product Specifications

- Blue

- Painted

- 12 Months

- Electricity

- Semi Automatic

- Industrial

HOT PLATE FOR END CAP CURING Trade Information

- GURUGRAM

- Cash in Advance (CID), Paypal, Cash Advance (CA)

- 50 Piece Per Month

- 01 Week

- No

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

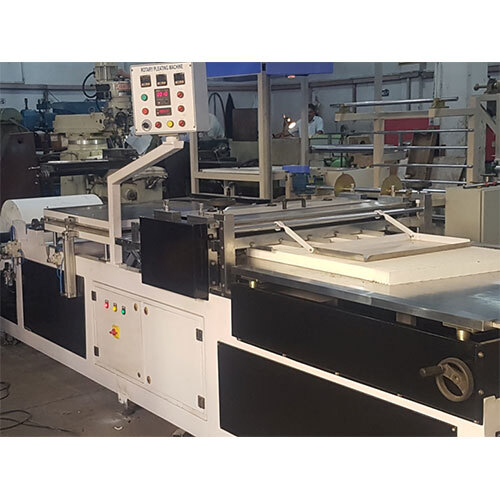

Are you looking forEnd Cap Curing Hot Plate?Kanwal Enterprisesis well-recognizedEnd Cap Curing Hot Plate Manufacturers In Haryanathat offer you the best quality products to meet your industry need. We blend our innovation and creativity to bring exceptional solutions. OurEnd Cap Curing Hot Plateis highly durable and robust construction that helps them to stand out of the curve. We work on our toes to deliver the best designEnd Cap Curing Hot Platethat is highly functional and needs less maintenance. Our End Cap Curing Hot Plate is beneficial to boost the productivity of your industry.

State-Of-Art-Infrastructure

Our complete range is manufactured in our in-house manufacturing facility and is equipped with modern machinery and the latest technology. We are capable enough to design the End Cap Curing Hot Plate with top-quality material and with the utmost precision. We work beyond boundaries to deliver you nothing but the best. We have a well-trained and experienced team of professionals who never mind putting extra effort into checking the quality standard of our End Cap Curing Hot Plate before delivering it to the end user. We strictly follow the industry norms.

Features Of Our End Cap Curing Hot Plate

- High-functionality

- Excellent and smooth finishing

- Corrosion and rust resistant

- Long functional life

- Customized as per the client's demand

- Eminent performance

- Rigid and robust structure

Get The Quality Assured End Cap Curing Hot Plate Now!

We are counted among Top10 End Cap Curing Hot Plate Exporters And Suppliers In India, are here to deliver you quality End Cap Curing Hot Plate at an affordable range. We are dedicated to catering to specific customer designs. So without any delay, get in touch with our experts to clear all your doubts. So, if you want to place your order, send enquiries on the website or directly call us.

Hot Plates for End Cap Curingapplications are available in maximum hot plate lengths of 950mm and widths of 500mm. Further, the maximum outer diameter for capping the machine is of 460mm. The system is also provided with aluminum casting heaters to achieve uniform distribution of heat and alarm system for indicating the completion of the cycle. Some of the other features of these end cap curing hot plates include digital temperature indicators & controllers, mild steel fabricated structures and latest technology based control panel for precision handling of involved operations.

Specifications

- Max length of hot plate 950mm.

- Max. width of hot Plate 500mm.

- Max outer diameter for cap is 460mm

- AL. casting heaters for uniform distribution of heat. Alarm to indicate the completion of the cycle.

- Hot plate fitted with digital temp indicator & controller.

- MS fabricated structure.

- Control panel for above.

Precision End Cap Curing

Our blue hot plate provides reliable, uniform heating ideal for curing end caps with accuracy. The semi-automatic operating system enhances consistency and ease of use, delivering optimal performance for industrial production lines. Designed for durability, it features a painted surface that withstands frequent use.

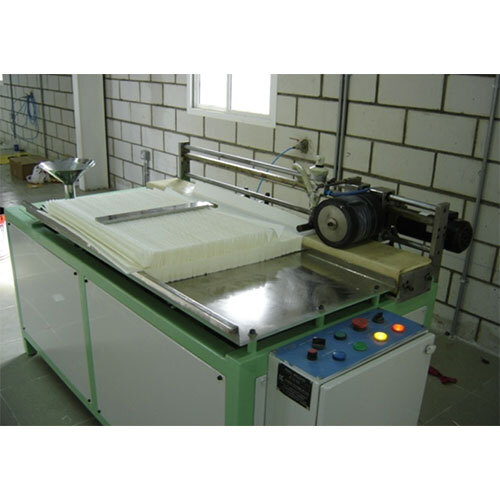

Industrial-Grade Reliability

Crafted for industrial applications, this hot plate is engineered to operate efficiently under demanding conditions. It is powered by electricity, ensuring stable operation and easy integration into modern manufacturing setups. The 12-month warranty offers customers additional peace of mind.

FAQ's of HOT PLATE FOR END CAP CURING:

Q: How is the Blue Hot Plate for End Cap Curing used in industrial applications?

A: This hot plate is typically employed in industrial settings for curing end caps during the manufacturing process. Operators place the end caps on the heated surface, activating semi-automatic controls to ensure precise and uniform curing.Q: What is the process for operating the hot plate?

A: To operate, simply connect the unit to an electrical source, set the desired temperature, and use the semi-automatic controls to initiate curing. The painted surface ensures optimal heat transfer and easy cleaning after use.Q: When is it appropriate to use this hot plate in production?

A: The hot plate is best utilized during the finishing phase of end cap manufacturing, specifically when a controlled and uniform cure is crucial for product durability and reliability.Q: Where can I purchase or source the Blue Hot Plate for End Cap Curing in India?

A: You can obtain this hot plate from authorized distributors, exporters, manufacturers, suppliers, and traders throughout India, making it accessible for a wide range of industrial users.Q: What are the primary benefits of using this hot plate for end cap curing?

A: Key benefits include increased consistency in curing, improved production efficiency, robust construction with a painted finish, and the assurance of a 12-month manufacturer warranty.Q: How does the semi-automatic operation improve the curing process?

A: The semi-automatic system reduces manual effort, minimizes human error, and maintains consistent temperatures, ensuring every end cap is cured to the same standard.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese