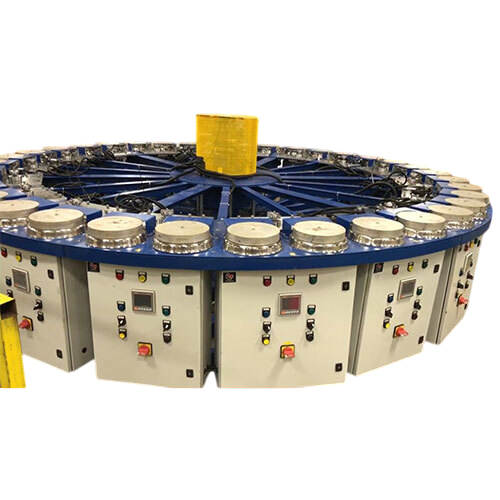

Hot melt applicator for filters

Product Details:

- Control System Fully Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color White,Blue

- Warranty 12 Months

- Click to View more

X

Hot melt applicator for filters Price And Quantity

- 1 Piece

Hot melt applicator for filters Product Specifications

- Automatic

- White,Blue

- 220 Volt (v)

- Electricity

- Painted

- 12 Months

- Industrial

- Fully Automatic

Hot melt applicator for filters Trade Information

- 2-3 Piece Per Day

- 1 Days

Product Description

Experience triumphant results and elite performance with our Hot Melt Applicator for Filters, engineered for industrial excellence. Operate confidently with a fully automatic control system, intuitive interface, and 220V electrical efficiency. This wondrous machine, painted in striking white and blue, delivers consistent results and excellent savings on every order. Distributors, exporters, manufacturers, suppliers, and traders across India trust its robust design and reliable 12-month warranty. Order today to streamline your production and achieve admirable, cost-effective filter assembly outcomes.

Premium Applications and Machine Features

The Hot Melt Applicator for Filters is ideal for a diverse range of industrial settings, efficiently bonding filter elements in manufacturing plants and assembly lines. Its key features include a fully automatic operation, sturdy build, painted surface protection, and a user-friendly interface. The main advantage lies in its unwavering consistency and reduced manual intervention, guaranteeing high productivity and flawless filter quality. Efficient, precise, and reliable, it becomes an indispensable asset for prolific industrial usage.

Payment Terms, FOB Port, and Packaging Offerings

We offer competitive list prices with the advantage of flexible payment terms tailored to your procurement needs. Freight arrangements are available, with FOB port locations throughout India to streamline shipment logistics. Each hot melt applicator is meticulously packaged to ensure safe transit. By partnering with us, your investment arrives secure and ready for use, reflecting our commitment to both cost-efficiency and reliability throughout the purchasing process.

Premium Applications and Machine Features

The Hot Melt Applicator for Filters is ideal for a diverse range of industrial settings, efficiently bonding filter elements in manufacturing plants and assembly lines. Its key features include a fully automatic operation, sturdy build, painted surface protection, and a user-friendly interface. The main advantage lies in its unwavering consistency and reduced manual intervention, guaranteeing high productivity and flawless filter quality. Efficient, precise, and reliable, it becomes an indispensable asset for prolific industrial usage.

Payment Terms, FOB Port, and Packaging Offerings

We offer competitive list prices with the advantage of flexible payment terms tailored to your procurement needs. Freight arrangements are available, with FOB port locations throughout India to streamline shipment logistics. Each hot melt applicator is meticulously packaged to ensure safe transit. By partnering with us, your investment arrives secure and ready for use, reflecting our commitment to both cost-efficiency and reliability throughout the purchasing process.

FAQ's of Hot melt applicator for filters:

Q: How does the hot melt applicator enhance filter production efficiency?

A: By automating adhesive application, the hot melt applicator minimizes manual labor, ensuring precise and consistent adhesive deposits, resulting in higher throughput and improved filter quality.Q: What are the main industrial applications for this machine?

A: This applicator is mainly used in filter manufacturing plants, assembly lines, and all industrial environments where consistent and durable filter bonding is required.Q: When should maintenance be scheduled for this equipment?

A: Routine maintenance is typically recommended every six months or as needed, depending on the machine's usage intensity and operational environment.Q: Where is the hot melt applicator manufactured and can it be exported?

A: Our hot melt applicators are manufactured in India and we export to international markets, offering global distribution for diverse industry needs.Q: What is the installation process upon delivery?

A: The installation process is straightforward, with clear instructions provided. Our technical team is available for remote or on-site support as needed to ensure smooth commissioning.Q: How does the warranty benefit the customer?

A: The included 12-month warranty covers manufacturing defects and provides peace of mind, supporting your business with timely assistance and spare parts if required.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese