ADHESIVE EDGE DRYING

Product Details:

- Machine Type ADHESIVE EDGE DRYING

- Control System Fully Automatic

- Frequency 50 Hertz (HZ)

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Click to View more

ADHESIVE EDGE DRYING Price And Quantity

- 1 Piece

ADHESIVE EDGE DRYING Product Specifications

- ADHESIVE EDGE DRYING

- Painted

- 12 Months

- Automatic

- Fully Automatic

- Electricity

- Industrial

- 50 Hertz (HZ)

- 220 Volt (v)

ADHESIVE EDGE DRYING Trade Information

- GURUGRAM

- Cash Advance (CA)

- 10 Piece Per Month

- 01 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

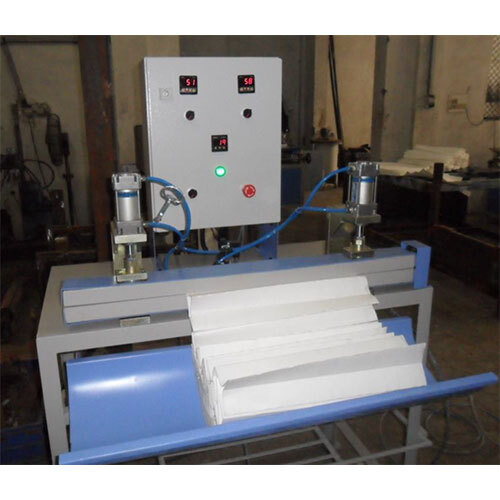

With the aim to serve complete solution to our clients, we are engaged in offering Adhesive Edge Drying Machine at nominal prices. It is manufactured using high quality materials and cutting edge technology. This drying machine is widely used for drying adhesive on applied at the edges of the packets and pouches. In addition to this, it is best known for its easy usage, corrosion resistance and rugged construction. Clients can avail this machine from us in varied specifications.

Fostered with immense years of industry experience, we are involved in offering high quality Adhesive Edge Drying Machine. This machine is well suited for drying the adhesive edge of pouches and packets. Our seasoned professionals manufacture this drying machine by making use of high grade components with the help of pioneering techniques. Also, we offer this Adhesive Edge Drying Machine at competitive rates to the clients.

Features:

- Drying cycle controlled by timer

- Platform surface covered by Teflon cloth

- Auto lifting of the platform after completion of one roll

- Support platform for resting of pack

Efficient Automatic Control System

The Adhesive Edge Drying Machine features a sophisticated fully automatic control system, eliminating manual intervention and boosting operational efficiency. The automatic settings minimize human error and ensure every batch receives uniform drying. This not only elevates productivity but also enhances workplace safety by reducing operator involvement in the process.

Industrial-Grade Durability and Design

Constructed for rigorous industrial use, this machine features a painted surface treatment to resist wear and corrosion. The equipment is powered by a reliable electric system, operating at 220 volts and 50 Hertz, making it universally compatible with standard industrial power setups. The build quality guarantees prolongued service life and reduced maintenance costs.

FAQ's of ADHESIVE EDGE DRYING:

Q: How does the fully automatic control system improve the adhesive edge drying process?

A: The fully automatic control system simplifies operation by managing the drying process without manual input, ensuring uniform results and reducing time spent on supervision. This leads to greater efficiency and consistent product quality.Q: What applications is the Adhesive Edge Drying Machine suitable for?

A: This machine is tailored for industrial applications, accommodating various sectors needing efficient and consistent adhesive edge drying, such as packaging, textiles, and manufacturing industries.Q: When is it ideal to use this Adhesive Edge Drying Machine?

A: The machine is most advantageous when consistent, high-volume adhesive drying is necessary and manual methods would be too slow or lack uniformity. Its automatic controls make it suitable for continuous operation.Q: Where can this machine be installed and operated?

A: The equipment is designed for industrial environments throughout India and can be installed in factories, production plants, and assembly lines where adhesive edge drying forms part of the workflow.Q: What is the process for operating the machine?

A: Simply connect the machine to a standard 220V electricity supply, set the desired parameters on the control system, and the automatic operation will handle the rest. Minimal supervision is needed once the process parameters are configured.Q: What are the main benefits of using this machine in industrial applications?

A: Some key advantages include faster adhesive drying times, improved product consistency, minimization of manual labor, enhanced workplace safety, and a painted surface treatment that increases overall machine lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese